Disruptions and the Shift in Healthcare Supply Chains

The COVID-19 pandemic has forever altered the landscape of healthcare supply chains around the globe. As hospitals scrambled to secure necessary medical supplies, from personal protective equipment (PPE) to ventilators, it became startlingly evident that heavy reliance on global supply networks was a vulnerability. Various governments, compelled by urgency and necessity, realized they could no longer depend solely on imports to stave off shortages during crises.

Frequent reports of dwindling supplies highlighted significant issues with existing processes. Countries like the United States and those in Europe witnessed firsthand the peril of outsourcing critical healthcare items to distant locations. As a result, many are re-evaluating their dependency on international supply chains, recognizing the need for a more resilient and sustainable approach to medical manufacturing.

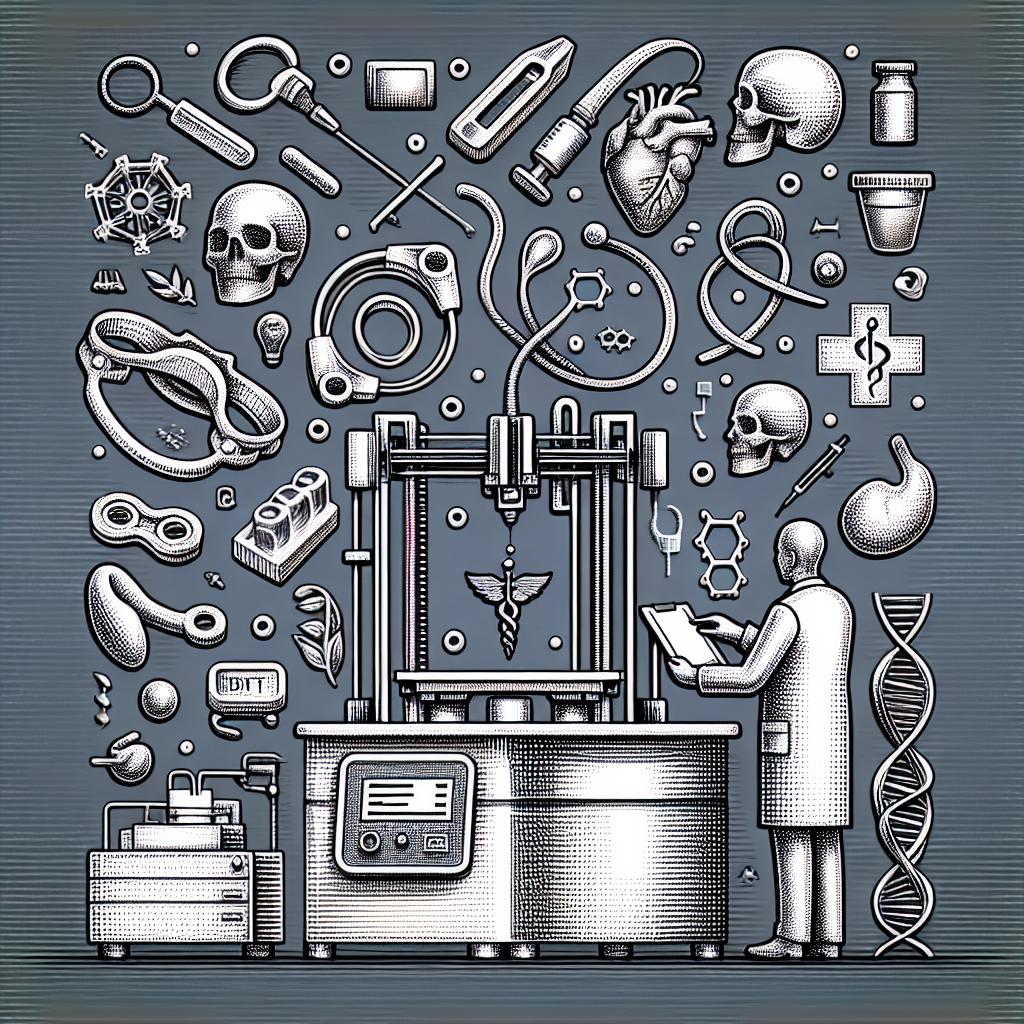

The Emergence of 3D Printing in Healthcare

Amid these challenges, a promising solution has emerged: 3D printing. This revolutionary technology, long associated with rapid prototyping and the production of various consumer goods, rapidly found its niche in medical fields. With the capability to manufacture essential medical supplies on demand—right at the point of care—it addresses many obstacles presented by traditional manufacturing.

The prospect of 3D-printed medical devices presents an innovative stopgap during crises. For instance, when standard face shields and ventilator parts were rapidly running out, healthcare professionals and organizations turned to their desktop 3D printers. Innovations sprang from grassroots movements and collaborative efforts among facilitators and driving organizations, intensifying the focus on leveraging additive manufacturing technology.

Yet recently, various case studies showcasing the effectiveness of 3D printing in healthcare have emerged, persuading nations and enterprises alike to invest heavily in this technology. Hospitals employed 3D printers for creating custom prosthetics, tailored surgical instruments, and even patient-specific models for preoperative planning. This adaptability captures the necessity of not only making healthcare resources available, but customizing them to current demands, evolving a scalable production premise that can pivot from emergency response back to everyday operational needs.

Encouragement of Domestic Production for Self-Sufficiency

As nations mobilize to ensure they are not caught off guard in future crises, a resurgence of domestic manufacturing is increasingly recognized as a strategic priority. Governments are launching incentives to bolster local industries capable of 3D printing essential medical supplies. The idea of self-sufficiency resonates strongly, particularly in the exploration of advanced manufacturing capabilities that bypass logistic dependencies and shrink lead times.

This motivation stems not just from a desire to address immediate shortcomings but acknowledges an impending need for agility in healthcare manufacturing. Countries are realizing that promoting local production can serve public health efficiently, ensuring essential supplies are accessible when the demand suddenly skyrockets, as witnessed during the pandemic.

Challenges of Quality Control and Regulation

Despite its promise, the widespread adoption of 3D printing in healthcare raises questions about quality control and regulatory standards. Unlike traditional manufacturing methods, which are governed by systematic regulations, the inherently flexible nature of 3D printing can lead to challenges in maintaining consistent quality across different production runs.

Regulating bodies, including the Food and Drug Administration (FDA) in the U.S., have started to establish frameworks around 3D-printed medical devices. Ensuring that 3D-printed products comply with stringent medical safety standards is critical, especially as the technology becomes more widely used for direct applications in patient care. The assurance of quality, reliability, and safety must remain paramount as nations navigate this brave new frontier.

The Future Landscape of Medical Supply Chains

The intersection of 3D printing technology with healthcare supply chains highlights an urgent re-evaluation of future manufacturing practices. The flexibility afforded by additive manufacturing could potentially offer a solution to meeting unpredictable patient needs while minimizing geographical vulnerabilities.

The lessons learned from the pandemic—supply chain volatility, the necessity for local production capabilities, and regulatory complexity—continue to shape effects felt across different sectors outside of healthcare, influencing discussions about other manufacturing industries.

As progress in 3D printing accelerates, it will usher in opportunities for innovation that can guarantee self-sufficiency, mitigate vulnerabilities, and reinforce resilience in medical supply chains across the globe. It would be prudent for policymakers to consider these advancements as part of a holistic approach towards improving healthcare systems and fostering economic stability.

Conclusion: Navigating Untamed Frontiers

The COVID-19 pandemic has undeniably shifted the paradigm of medical supply chains. As the industry moves towards a technologically empowered future, the vision of 3D printing as a cornerstone for transforming healthcare manufacturing can only grow clearer. With the evolving landscape of self-sufficiency and regulatory adaptation, a fruitful navigation of challenges ahead awaits.

As nations and healthcare systems turn towards 3D printing and other homegrown solutions, the lessons learned will not only refine the act of responding to crisis but affirm the importance of continuous innovation as health care models evolve.